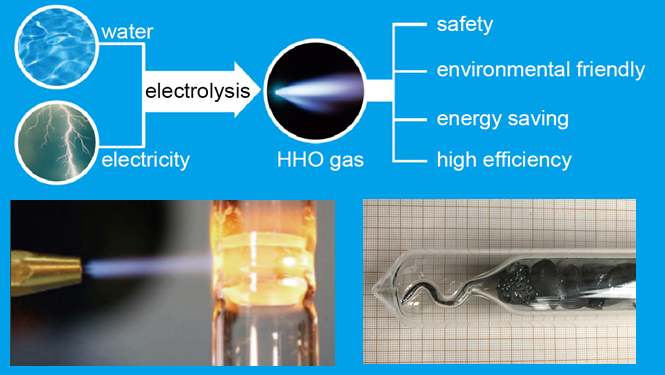

Using water as the raw material, It decompose water into oxygen and hydrogen gas through electrolysis. Hydrogen can be burned, and oxygen supports combustion.

Oxyhydrogen Flame Sealing Machine

Using water as the raw material, It decompose water into oxygen and hydrogen gas through electrolysis. Hydrogen can be burned, and oxygen supports combustion. These two gases ignite to form oxyhydrogen flame. The hydrogen oxygen flame sealing machine has the following major characteristics:

1. The hydrogen and oxygen gas comes from electrolysis of water, and the gas is clean and pollution-free.

2. Gas is produced and used on-site without storage.

3. Hydrogen and oxygen are generated in the optimal combustion state of 2:1, ensuring complete combustion.

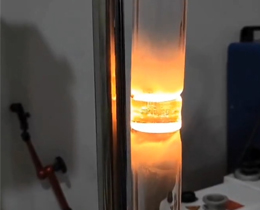

4. 2800℃High temperature concentrated oxyhydrogen flame without divergence, which is suitable for precise heating workpieces.

5. When the pressure reaches 0.2Mpa, the equipment will automatically stop producing gas, and when it falls below 0.08Mpa, the equipment will automatically resume producing gas.

6. The flame torch comes with a flame arrester, and the pipeline is equipped with the anti-backfire device. The machine has a wet anti backfire system, pressure control, pressure relief system, and other inside safety protection devices to ensure the safety of use.

7. Accessories include: a flame torch, flame nozzles of different sizes, a flame arrester, a set of flame torch holder, a quartz glass tube cutter, and 4m gas tube.

| Model: | TX-HO600+TX-V10 |

| Input Voltage: | 220V |

| Gas Output: | 600L/h |

| Flame Temperature: | 2800℃ |

| Rotating Speed: | 0-20r/min |

| External Diameter of Sealing Tube: | 8-45mm |

| Vacuum Connection: | KF25 |

| Air Escape Valve: | KF16 |

| Sealing Method: | pull sealing, plug sealing |

| Vacuum Leakage Rate: | 2*10-6Pa m3/S |

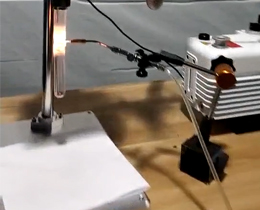

Quartz Vacuum Sealing System

1. When the quartz tube rotates automatically, the principle of vacuum dynamic sealing is adopted, and the vacuum leakage rate is vacuumed while rotating to maintain the corresponding vacuum degree. Uniform heating while automatic rotation, high sealing efficiency, easy to learn and use, safe and reliable.

2. Suitable for vacuum sealing of quartz tubes of different lengths, and can be tilted and vertical to meet different needs.

3. Reserved filling gas interface, which can be matched according to user needs.

4. Digital displayed rotation speed is adjustable from 0 to 40 revolutions per minute.

5. Simple operation, compact structure, precise design, compact size, cost-effective, and able to achieve optimal vacuum degree.

6. Equipped with a powder backflow prevention device to prevent the powder material inside the quartz tube from being pumped out by a vacuum pump, protecting the vacuum pump and reducing material consumption.

7. The product comes standard with one quartz tube connector, and various of quartz tube connectors can be customized. The sealing machine can be used by changing the size of the connector to match the quartz tube.

8. It is equipped with an isolating valve, which can be used together with the glove box to seal the tube.

9. The joints connected to the vacuum pump are flexible and matched.

Product Feature

1. plug sealing (fusing the glass rod with the glass tube inner wall)or quartz tube pull sealing methods available.

2. Automatic rotary dynamic sealing with simple operation and uniform heating.

3. Standard quick interface for easy connection to the vacuum system, and also easy installation and fixation of quartz tubes.

4. Compact structure, precise design, safe and reliable.

Oxyhydrogen generator quartz scientific glass vacuum sealing machine is mainly used for oxygen-free and water-free vacuum-sealed storage of samples. The whole setup system consists of oxyhydrogen generator, glass tube vacuum sealing machine, and vacuum pump.