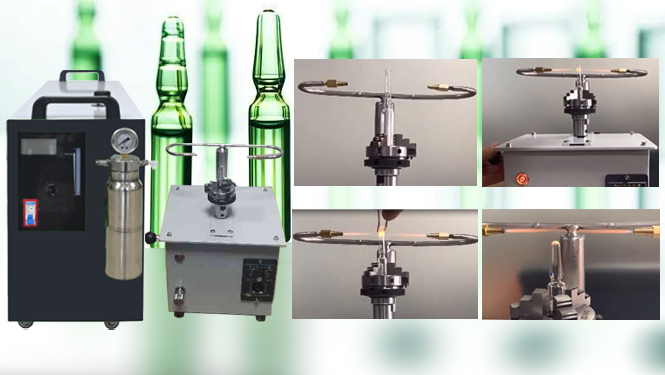

Ptxson rotary ampoule sealing machine TX-HO400 + TX-R2 can seal diffrent size of bottles with 60bottles per minute. We aim to provide you one-stop of oxyhydrogen flame ampoule quartz glass sealing solution.

If you want more fast and uniform sealed ampules,the rotary oxyhydrogen flame ampoule sealing machine will be best choice. We design it from such features of operability, cost-effectiveness, melting speed and quality.Oxyhydrogen flame pull sealing way combined with rotary chuck workbench can seal diffrent size of bottles with 60bottles per minute.Ptxson is aim to provide you one-stop of oxyhydrogen flame ampoule quartz glass sealing solution.

| Model | TX-HO400 + TX-R2 |

| Max. Gas Output | 400L/h |

| AC Voltage(V) | 220/110 |

| Rated Power | 1400W |

| Operation Mode | semi-automatic rotation |

| Water Feed | manual |

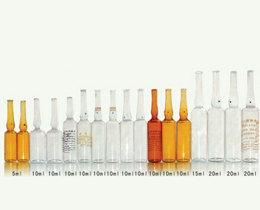

| Ampoule Size | 1-50ml |

| Ampoule Sealing Torch | rotary double flame sealing torch |

| Dimension(L*W*H-mm) | 760*300*540 |

| Gross Weight(kg) | 45 |

How does it work?

Putting ampoule bottles on the rotating flame sealing device and fixed it with chuck.Push the rod inward to seal bottles rotation automatically, and you should use tweezers to pull the bottle mouth upwards. After ampoule sealing finished,pull the rod outward to stop bottles automatically.

Oxyhydrogen generator quartz scientific glass vacuum sealing machine is mainly used for oxygen-free and water-free vacuum-sealed storage of samples. The whole setup system consists of oxyhydrogen generator, glass tube vacuum sealing machine, and vacuum pump.