The set of equipment consists of the high vacuum rotary sealing system, the high vacuum pipeline, air inlet, air bleed port, vent valve, and flange of glass tube. The molecular pump vacuum system is a clean high vacuum acquisition device. This device is a vacuum acquisition system based on the principle of vacuum knowledge, utilizing a combination of mechanical pumps and turbomolecular pumps.

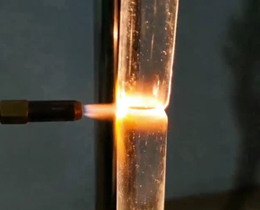

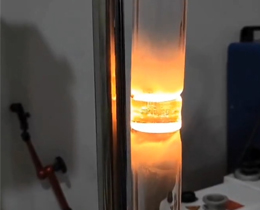

The set of equipment consists of the high vacuum rotary sealing system, the high vacuum pipeline, air inlet, air bleed port, vent valve, and flange of glass tube. Vacuum sealing of daily high-purity raw materials such as quartz glass tube vacuum sealing or borate glass vacuum sealing are used in universities and research laboratories. The glass tubes are batch sealed in the factory. After the quartz glass tubes are melt, the sample is completely isolated from the external air, effectively protecting the sample that is sensitive to air. The sample can be sintered or transported over long distances and transferred between glove boxes after material samples under vacuum sealing. Vacuum quartz tube sealing machine are available in various models, including 1-3 workstations and customized ones.

The molecular pump vacuum system is a clean high vacuum acquisition device. This device is a vacuum acquisition system based on the principle of vacuum knowledge, utilizing a combination of mechanical pumps and turbomolecular pumps. It has the characteristics of fast startup, high vacuum degree, and easy operation,which is widely used in various fields such as surface analysis, accelerator technology, plasma technology, electric vacuum device manufacturing, and vacuum. The main components of the equipment mainly include vacuum measurement system, vacuum chamber, valves and vacuum pipelines, electrical control system, etc

| Product Name: | TX-Q20 double workstations quartz vacuum sealing system |

| Input Voltage: | 220V |

| Rotation Speed: | 1-20rpm |

| Vacuum Connection: | KF25 |

| Air Escape Valve: | KF16 |

| Protective Gas Inlet: | 6mm ferrule joint |

| Rotating Speed: | 0-20r/min |

| External Diameter of Sealing Tube: | 8-45mm |

| Wall Thickness | ≤2mm |

| The Length of Glass Tube | 500mm |

| Sealing Method: | pull sealing, plug sealing |

| Vacuum Leakage Rate: | ≦2×10-6Pa·m3/S |

| Standard Accessories: | KF25 vacuum baffle valve *1pcs; KF25 corrugated pipe *1 pcs;KF16 vent valve *1 pcs; KF16 vacuum mechanical pressure gauge *1pcs; Flame torch holder*1pcs; polarizers*1pair; high-temperature gloves*1pair; quartz glass clamp*1pcs; KF16 clamp *1pcs; KF25 clamp *2pcs; φ 6mm intake pipe *3 meters; power adapters*1pcs |

| Product Name: | TX-150YCF molecular pump vacuum system |

| AC Voltage: | 220V |

| Rated Power: | 1.5KW |

| Front stage pump: | bipolar 4-vane vacuum pump |

| Front stage pumping rate: | 2.2L/s |

| Max. pressure of the front stage pump: | ≤ 5Pa |

| Molecular pump: | FF-100/150 51000 rpm |

| Molecular pump pumping rate: | 140L/S |

| Starting time of molecular pump: | ≤ 2min |

| No-load max. pressure: | ≤ 1X10-4Pa |

| Vacuum range: | cold cathode standard gauge 1E+2 to 1E-5 Pa |

| Extraction interface: | KF25 |

| Valve type: | KF25 manual baffle valve |

| Environmental temperature: | 5-32 ℃ |

| Cooling type: | air cooling |

| Humidity: | ≤ 80% |

| Noise: | <60 decibels |

| Dimension: | 330*495*600mm |

| Gross Weight: | 55kg |

Functional Characteristics

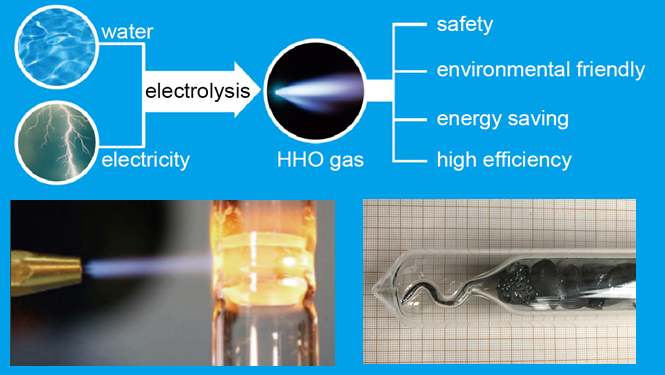

Oxyhydrogen generator quartz scientific glass vacuum sealing machine is mainly used for oxygen-free and water-free vacuum-sealed storage of samples. The whole setup system consists of oxyhydrogen generator, glass tube vacuum sealing machine, and vacuum pump.