We independently developed quartz glass tube vacuum sealing system,which is simple and convenient to operate, It uses a unique rotating sealing flange to adjust the sealing speed of the test tube. At the same time, it can be sealed without manually rotating the test tube, greatly improving the sealing efficiency of the test tube.

The whole set of system consists of the single station rotary vacuum sealing machine,oxyhydrogen generator,vacuum pump, quartz tube clamps etc. Standard customized quartz tubes and glass rods ensure their matching with specially designed glass joints, further improving the vacuum degree of quartz tube sealing, achieving semi-automatic sealing, improving working efficiency, and higher standard of vacuum sealing.

How to seal quartz glass tube for material samples under vacuum sealing?

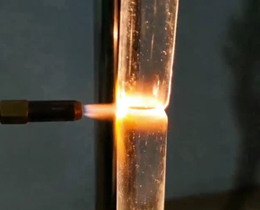

There are two sealing method: neck sealing with glass rod and pull sealing

| Model: | TX-Q10+TX-8 mechanical vacuum pump |

| Input Voltage: | 220V |

| Rotation Speed: | 1-20rpm |

| Vacuum Degree: | ≤ 5Pa(mechanical pump), ≤ 5×10-4Pa (molecular pump) |

| Rotating Speed: | 0-20r/min |

| External Diameter of Sealing Tube: | 8-45mm |

| Wall Thickness | ≤2mm |

| The Length of Glass Tube | 200mm |

| Vacuum Connection: | KF25 |

| Air Escape Valve: | KF16 |

| Sealing Method: | pull sealing, plug sealing |

| Vacuum Leakage Rate: | ≦2×10-10Pa·m3/S |

Functional Characteristics

The set of equipment consists of the high vacuum rotary sealing system, the high vacuum pipeline, air inlet, air bleed port, vent valve, and flange of glass tube. The molecular pump vacuum system is a clean high vacuum acquisition device. This device is a vacuum acquisition system based on the principle of vacuum knowledge, utilizing a combination of mechanical pumps and turbomolecular pumps.

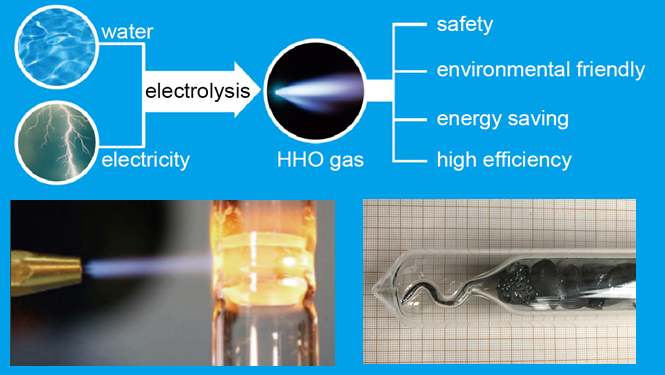

Using dynamic sealing technology to automatically rotary and hold quartz scientific glass with vacuum or argon backfill to prevent sample oxidation. You can chooe oxygen/propane or oxyhydrogen flame torch to melt glass tube. Different size of glass tube clamps can be supplied with your demand.