Water electrolysis Technology: Alkaline electrolysis

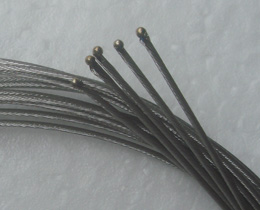

Application:jewelry welding,acrylic flame polishing

Power Cord: US plug,EU plug, UK plug, AU plug etc

About Oxyhydrogen Flame

Hydrogen is a clean and carbon-free energy.The combustion substance of oxyhydrogen flame is only water vapor. It is green eco-friendly on-site gas generation equipment, no gas cylinder is needed.Oxyhydrogen gas is produced on demand at anytime and anywhere. Oxyhydrogen flame is concentrated and its temperature is up to 2800℃.Therefore,it can be used for welding and cutting of various non-ferrous metal.

Oxyhydrogen Generator for Jewelry Welding

1.It can weld kinds of chain and string jewelry which are made of platinum,gold,silver,copper,stainless steel and etc.

2.It is also repairing and casting tiny sand holes in the process of jewelry casting and repair.

| Model | TX-HO150 |

| AC Voltage(V) | 220/110 |

| Rated Power(KW) | 0.6 |

| Gas Output(L/h) | 0-150 |

| Working Pressure | 0.1-0.14Mpa |

| Max. Water Consumption(L/h) | 0.09 |

| Water Feed | manual |

| Dimension(L*W*H-mm) | 530*300*540 |

| Weight(kg) | 17 |

| Vertilation Space Requirement(mm) | 200 |

Oxyhydrogen Advantage

Jewelry processing requires small and soft oxyhydrogen flame.Generally,Ptxson oxy-hydrogen flame welding machine is high recommended. The small oxyhydrogen generators is characterized by easy to carry. The speed of oxyhydrogen flame is very awesome and the welding points are very smooth and beautiful. What’s more,the oxyhydrogen generator can be together with multiple flame torches for several operators.

The oxyhydrogen generator uses electrolytic powder (potassium hydroxide) plus purified water solution

as electrolyte liquid,and adopts the principle of water electrolysis to electrolyze hydrogen and oxygen gas from water. Hydrogen is used as the fuel gas, oxygen is used as the combustion gas, and hydrogen oxygen gas is mixed in the optimal combustion ratio of 2:1.