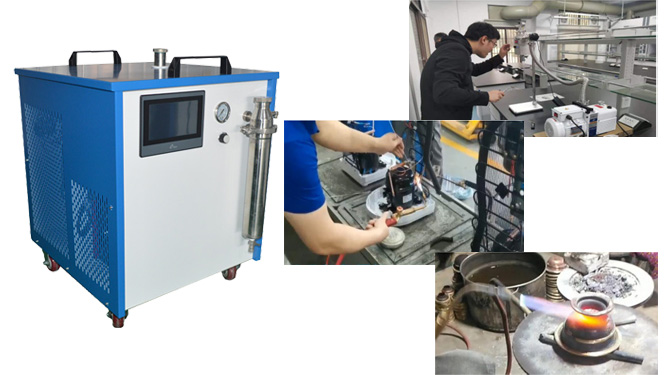

The oxyhydrogen generator uses electrolytic powder (potassium hydroxide) plus purified water solution

as electrolyte liquid,and adopts the principle of water electrolysis to electrolyze hydrogen and oxygen gas from water. Hydrogen is used as the fuel gas, oxygen is used as the combustion gas, and hydrogen oxygen gas is mixed in the optimal combustion ratio of 2:1.

Hydrogen and oxygen generator is a clean energy equipment which produce H2 and O2 from water by electrolyzing water. Hydrogen is used as fuel and oxygen is used for combustion-supporting without additional gas cylinders. It can replace carbon-containing gases such as acetylene, natural gas and liquefied gas. It has the characteristics of safety, high efficiency, environmental protection and energy saving. AC 380V or 220V is rectified into direct current by high-efficiency IGBT inverter power supply, and applied to both ends of the electrolytic cell. The electrolyte (25% potassium hydroxide) in the electrolytic cell is subjected to direct current and electrochemical reaction occurs. The cathode produces hydrogen and the anode produces oxygen.

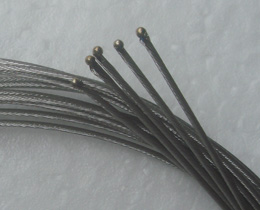

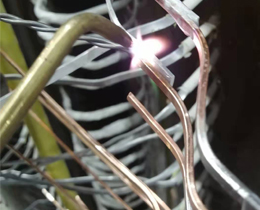

The oxyhydrogen torch produce high temperature, high energy and concentrated oxyhydrogen flame,which weld the joint of several enamel copper wires,coil wire to cable wire. The solder joints are strong and beautiful, no virtual soldering, no black smoke and no carbon emission.

| Model Number | TX-HO1000 |

| AC Voltage Requirement(V) | 220 |

| Phase | single |

| Power Consumption(kw/h) | 3.5 |

| Max. Gas Output(L/h) | 1000 |

| Max. Working Pressure(kg/cm2) | 2 |

| Max. Water Consumption(L/h) | 0.54 |

| Water Feed | manual/automatic |

| Flame Modifier Feed | manual |

| Dimensions-L*W*H (mm) | 660*570*760 |

| Gross Weight(kg) | 90 |

| Ventilation Space Requirement(mm) | 400mm in each direction |

There are many advantages of oxyhydrogen welding

1.Reduce your production cost

2.Improve production efficiency and work conditions

3.Solve the safety issues

4.Fast welding & no cold joint

5.No carbon emission, Eco- friendly

6.No need to strip enamel on copper wire

7.Safety: No gas storage, used by demand

8.One machine can replace the acetylene oxygen gas bottles.

9.Energy saving: it can save 35%-57% fuel compared with propane and acetylene