The industrial oxyhydrogen generators adopt the alkaline electrolysis method to reduce the production cost and improve the high efficiency of electrolysis.3500L/h Oxyhydrogen flame welding machine is with flange type joint electrolytic cell,1., which can be disassembled for thorough maintenance and repair in the later stage. It is suitable for high flow gas production.

Ptxson Oxy-hydrogen Machine

The industrial oxyhydrogen generators adopt the alkaline electrolysis method to reduce the production cost and improve the high efficiency of electrolysis. It mainly includes generators, anti-tempering devices, power systems, axial fans,wash tank and circuit control systems.

For the first time of use,25%-28% concentration of potassium hydroxide(KOH) or sodium hydroxide(NaOH) is used to improve the electrolysis efficiency.Only purified water,distilled water or deionized water are added for the continuous daily use after the first time to make Electrolyte Solution (KOH). After the machine is running 1000 hours,it should replace the electrolyte,clean and maintain the machine.

| Model Number | TX-HO3500 |

| AC Voltage Requirement(V) | 380 |

| Phase | two |

| Power Consumption(kw/h) | 11 |

| Max. Gas Output(L/h) | 3500 |

| Max. Working Pressure(kg/cm2) | 2 |

| Max. Water Consumption(L/h) | 1.9 |

| Water Feed | automatic |

| Flame Modifier Feed | manual |

| Dimensions-L*W*H (mm) | 1200*770*1300 |

| Gross Weight(kg) | 340 |

| Ventilation Space Requirement(mm) | 400mm in each direction |

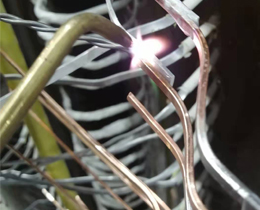

Oxyhydrogen generator welding machine have following functional features:

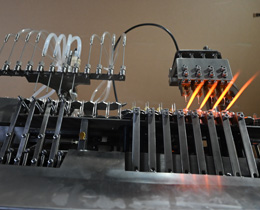

1.Radiator type electrolytic cell. Aluminum tube heat dissipation method has strong heat dissipation ability and the highest electrolysis efficiency. The hydrogen oxygen generator is with flange type joint, which can be disassembled for thorough maintenance and repair in the later stage. It is suitable for high flow gas production.

2.Real-time working status dynamic display. The equipment has the dynamic display of real-time status of water storage tank, electrolytic tank, water gas separation system, and indicator lights of automatic protection device.

3.24hours continuous working. The oxyhydrogen machine can meet the requirements of continuous running. With automatic water filling function, it can work 24hours non-stop water addition.

The oxyhydrogen generator uses electrolytic powder (potassium hydroxide) plus purified water solution

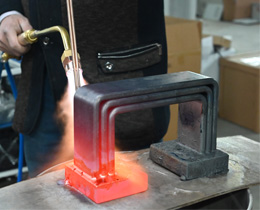

as electrolyte liquid,and adopts the principle of water electrolysis to electrolyze hydrogen and oxygen gas from water. Hydrogen is used as the fuel gas, oxygen is used as the combustion gas, and hydrogen oxygen gas is mixed in the optimal combustion ratio of 2:1.