Oxyhydrogen generator is quite safe since it does not require gas cylinders and no risks of leakage and explosion.

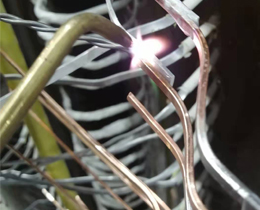

Oxyhydrogen generator consumes water and electricity,electrolyze water into H2 and O2,we can use H2 and O2 as source of flame replacing acetylene or natural gas or other fuel.

How to choose the right oxyhydrogen generator for welding enamel copper wire?

Oxyhydrogen welding machine is the best choice for welding motor enamelled wire. Three tips tell you how to choose the right oxyhydrogen generator.

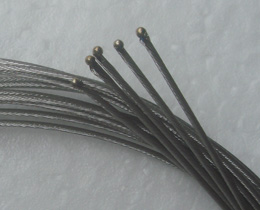

1.Firstly,the wire diameter of an enameled wire and wire quantity, and the square number of leading wires.

2.Secondly, what is the largest wire diameter specification required for welding, and what is the most commonly used wire diameter specification?

3.Thirdly, the number of stations that need to be welded at the same time.

| Model Number | TX-HO400 |

| AC Voltage Requirement(V) | 220/110 |

| Phase | single |

| Power Consumption(kw/h) | 1.4 |

| Max. Gas Output(L/h) | 400 |

| Max. Working Pressure(kg/cm2) | 2 |

| Max. Water Consumption(L/h) | 0.23 |

| Water Feed | manual |

| Flame Modifier Feed | manual |

| Dimensions-L*W*H (mm) | 710*250*510 |

| Gross Weight(kg) | 28 |

| Ventilation Space Requirement(mm) | 200 in each direction |

Functional Features

1.Pressure gauge: reading and displaying real-time pressure value.

2.Pressure control switch: stop gas production due to over pressure,and automatically resume gas production due to low pressure.

3.Auxiliary tank: it is also called filter tank. Pure water is added in the tank to filter hho gas. Alcohol or petroleum ether can be added to diffuse the oxyhydrogen flame and reduce the flame temperature.

4.Electrolyzer: independent multiple cylinder electrolytic cells.For 400L/h machine,there are four cells.One electrolytic cell produces 100L hho gas.

5.Power supply: one electrolytic cell corresponds to one power supply.

6.Anti-backfire flame arrestor: as the combustion speed of oxyhydrogen gas is fast,and the speed is 13m/s. The dry type flame arrestor of OH400 machine adopts the principle of hho gas only flowing out but not flowing in the gas tube, which can prevent flame from flowing back when backfire accurs.

The industrial oxyhydrogen generators adopt the alkaline electrolysis method to reduce the production cost and improve the high efficiency of electrolysis.3500L/h Oxyhydrogen flame welding machine is with flange type joint electrolytic cell,1., which can be disassembled for thorough maintenance and repair in the later stage. It is suitable for high flow gas production.