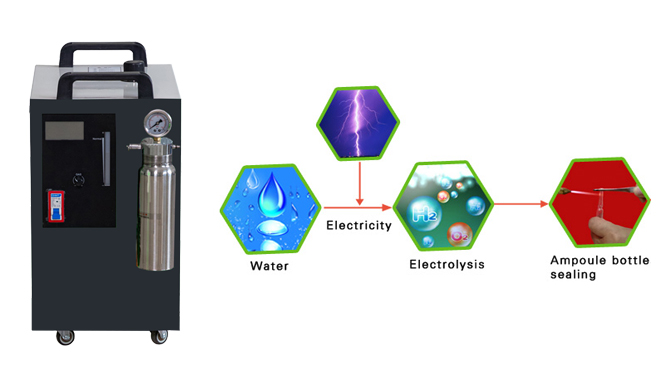

Oxyhydrogen flame generator use water and electricity to produce hydrogen and oxygen gas.

Oxyhydrogen flame generator use water and electricity to produce hydrogen and oxygen gas. After burning only left water steam,no pollution.We also have various safety devices are built in the machine, like flame torch anti-backfire, pipe flame arrester anti-backfire, internal pressure diagnosis of the machine, pressure relief system, etc.

| Model | TX-HO200A |

| Max. Gas Output | 200L/h |

| AC Voltage(V) | 220/110 |

| Rated Power | 800W |

| Operation Mode | manual by hand |

| Water Feed | manual |

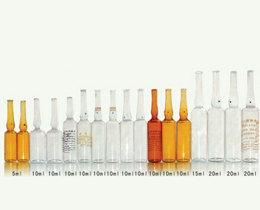

| Ampoule Size | 1-25ml |

| Ampoule Sealing Torch | single flame sealing torch |

| Dimension(L*W*H-mm) | 450*246*470 |

| Net Weight(kg) | 17 |

Why choose oxyhydrogen flame sealing machine?

Safety Operation

It produces and stops gas just turning on and off the machine,no gas stored and no pollution to the laboratory environment.

Convenient

Just adding pure water and power on to form oxyhydrogen flame.

High Efficiency

It forms stable oxyhydrogen flame by pull sealing. The finished ampoule bottles are 99% qualification rate.

Eco-friendly

It doesn’t produce CO2,CO, and NOx pollution substances. It is zero carbon emission and only water vapor after sealing ampoules.

We independently developed quartz glass tube vacuum sealing system,which is simple and convenient to operate, It uses a unique rotating sealing flange to adjust the sealing speed of the test tube. At the same time, it can be sealed without manually rotating the test tube, greatly improving the sealing efficiency of the test tube.