Add qualified electrolytic water (resistivity ≥1M Ω/cm, deionized water or distilled water) into the anode chamber of the electrolytic cell.

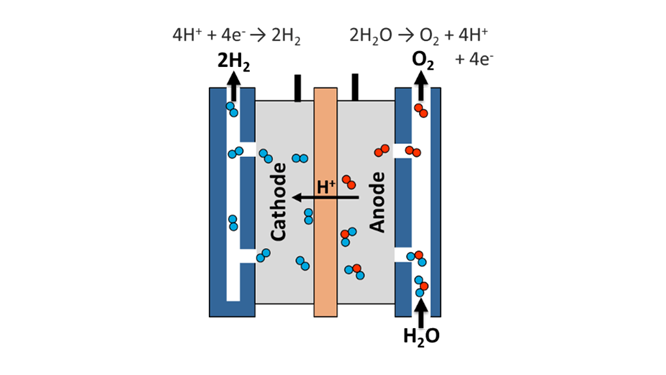

Add qualified electrolytic water (resistivity ≥1M Ω/cm, deionized water or distilled water) into the anode chamber of the electrolytic cell. After power on, the water will be immediately decomposed at the anode: 2H2O=4H++2O-2, the negative oxygen ions (O-2) decomposed into, and then electrons will be released at the anode to form oxygen (O2), which will be discharged from the anode chamber, and part of the water will be carried into the water tank. The water can be recycled, Oxygen is discharged into the atmosphere through a small hole on the cover of the sink. Hydrogen protons, in the form of hydrated ions (H+• XH2O), pass through the SPE ion membrane under the action of electric field force, and reach the cathode to absorb electrons to form hydrogen gas. After being discharged from the cathode chamber, they enter the gas-water separator where most of the water carried out from the electrolysis tank is removed. Hydrogen gas containing trace amounts of water is then humidified by a dryer, resulting in a purity of over 99.999%.

| Model | TX-1000 |

| Output Pressure | 0.4Mpa |

| Output Flow | 0-1000ml/min |

| Purity | >99.999% |

| Power | 560W |

| Gross Weight | 25.5KG |

| Dimension(L*W*H) | 420*280*450mm |

Product Features

1.Easy to operate, just turn on the power switch to produce hydrogen, with stable output pressure and digital flow indication, eye-catching and intuitive.

2.It only requires adding pure water for daily work, which can work continuously or intermittently, and the hydrogen output is stable.

3.It is safe and reliable, and the instrument has an over-voltage protection device.

4.The design of the gas circuit system is unique and there is no water return phenomenon.

5. Adopting a switching power supply to improve electrolysis efficiency.

25Nm3/h PEM solar powered hydrogen generator produces high purity of hydrogen 99.999% and a dew point -65°C. It has strong load adaptability with hydrogen production continuously adjustable between 0-120% and offers a quick response to load changes.

The 3000ml hydrogen generator has small light weight shape with the function of low-pressure gas production,high purity hydrogen output, and automatic tracking of hydrogen flow rate.

The pure hydrogen generator uses SPE technology to electrolyze pure water to produce high-purity hydrogen. It is a lightweight, efficient, energy-saving, and environmentally friendly high-tech patented gas generation equipment.