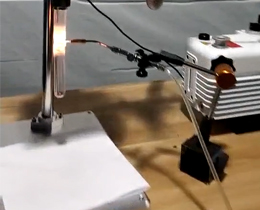

Oxyhydrogen generator quartz scientific glass vacuum sealing machine is mainly used for oxygen-free and water-free vacuum-sealed storage of samples. The whole setup system consists of oxyhydrogen generator, glass tube vacuum sealing machine, and vacuum pump.

Quartz glass vacuum sealing system

The quartz tube vacuum sealing system consists of oxyhydrogen generator, glass tube vacuum sealing machine, and vacuum pump.

1. It is suitable for different diameter glass tube sealing.

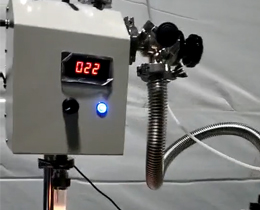

2. Automatically rotate the glass tube at a constant speed. The rotary speed is adjustable.

3. It can be equipped with the vacuum measurement part.

4. It can also be equipped with a protective gas interface and a vent valve to achieve high vacuum sealing condition.

5. 1-3 workstation sealing machines are available.

Oxyhydrogen generator for sealing

Hydrogen and oxygen is produced by electrolysis of water, which the hydrogen is used as fuel and oxygen as combustion. Ignition generates oxyhydrogen flame. It can replace traditional gas cylinders such as acetylene, coal gas, liquefied gas, and has the characteristics of safety, environmental protection, energy saving, and high efficiency.

| Model: | TX-HO1000+TX-V10 |

| The number of workstation | 1 |

| Input Voltage: | 220V |

| Gas Output: | 1000L/h |

| Flame Temperature: | 2800℃ |

| Rotating Speed: | 0-40r/min |

| External Diameter of Sealing Tube: | 8-45mm |

| Vacuum Connection: | KF25 |

| Air Escape Valve: | KF16 |

| Sealing Method: | pull sealing, plug sealing |

| Vacuum Leakage Rate: | 2*10-11Pa m3/S |

| Standard Accessories | 1pcs*vacuum flange, 1pcs*KF25 vacuum isolation valve, 1pcs*KF16 exhaust valve |

Product Feature

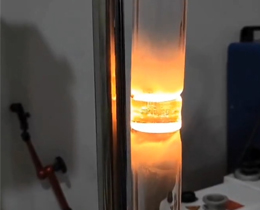

1. plug sealing (fusing the glass rod with the glass tube inner wall)or quartz tube pull sealing methods available.

2. Automatic rotary dynamic sealing with simple operation and uniform heating.

3. Standard quick interface for easy connection to the vacuum system, and also easy installation and fixation of quartz tubes.

4. Compact structure, precise design, safe and reliable.

We independently developed quartz glass tube vacuum sealing system,which is simple and convenient to operate, It uses a unique rotating sealing flange to adjust the sealing speed of the test tube. At the same time, it can be sealed without manually rotating the test tube, greatly improving the sealing efficiency of the test tube.

The set of equipment consists of the high vacuum rotary sealing system, the high vacuum pipeline, air inlet, air bleed port, vent valve, and flange of glass tube. The molecular pump vacuum system is a clean high vacuum acquisition device. This device is a vacuum acquisition system based on the principle of vacuum knowledge, utilizing a combination of mechanical pumps and turbomolecular pumps.