The working medium of oxyhydrogen generator is pure water and electricity, which is electrolyzed with water to produce hydrogen and oxygen gas. Purified water is then supplied and can be added at the daily time, It is operated with low cost and convenient to use.

How does the oxyhydrogen generator work?

Consume water +electricity to create oxy-hydrogen gas.

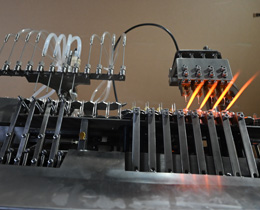

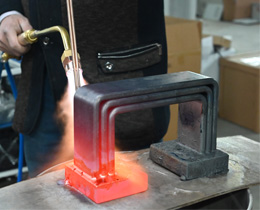

The oxy-hydrogen generator is an energy gas equipment that uses electrolyzed water technology to produce oxyhydrogen gas from water. Hydrogen is used as a fuel, and oxygen is used as a combustion-supporting device. It can replace carbon-containing gases such as acetylene, gas, and liquefied gas, and has high calorific value and flame concentration,no pollution, high production efficiency, energy saving and other advantages.

The electrolytic power supply reverses the 380V alternating current to a direct current connection to the oxyhydrogen plate, and the water is electrolyzed to hydrogen and oxygen. Through the cooling fan cooling, and the water vapor separation to produce output of mixed hydrogen and oxygen gas.

| Model Number | TX-HO6000 |

| AC Voltage Requirement(V) | 380 |

| Phase | two |

| Power Consumption(kw/h) | 21 |

| Max. Gas Output(L/h) | 6000 |

| Max. Working Pressure(kg/cm2) | 2 |

| Max. Water Consumption(L/h) | 3.2 |

| Water Feed | automatic |

| Flame Modifier Feed | manual |

| Shell Material | iron plate spray |

| Water Requirement | purified water or distilled water |

| Cooling Method | air cooling |

| Dimensions-L*W*H (mm) | 1310*950*1670 |

| Gross Weight(kg) | 480 |

| Ventilation Space Requirement(mm) | 400mm in each direction |

What are the features and benefits of oxyhydrogen generator?

1. The working medium of oxyhydrogen generator is pure water and electricity, which is electrolyzed with water to produce hydrogen and oxygen gas. Purified water is then supplied and can be added at the daily time, It is operated with low cost and convenient to use.

2. The oxyhydrogen generator produces gas on demand.Do not store gas, and gas production immediately. It is low pressure gas generator, and no risk of gas leakage and explosion.

3. Oxygen and hydrogen gas is formed by the decomposition of water, and it forms water vapor after gas combustion. No CO and carbon emission is produced during the machine operation, which is beneficial for the physical health of operators.

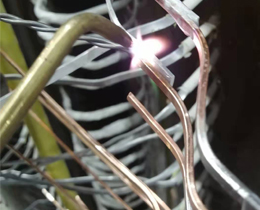

4. The temperature of the oxyhydrogen flame can be up to 2800℃with a concentrated flame. It can quickly seal various glass products and weld various non-ferrous metals, which is more than three times the speed of traditional gas systems.

5. Adopting imported IGBT inverter DC resonant power supply, it has high electrolysis efficiency, stable and adjustable electrolysis current, stable and adjustable gas production, and can work continuously 24 hours.

6. The electrolytic cell is formed using a large integrated mold, which has very high anti-explosion and anti-leakage performance and a long service life.

7. The safety system adopts a multi-level rotary water seal design, automatic detection and control of the safe water level, ensuring 100% anti-backfire reliability, ensuring safety and extending machine service life.

The oxyhydrogen generator uses electrolytic powder (potassium hydroxide) plus purified water solution

as electrolyte liquid,and adopts the principle of water electrolysis to electrolyze hydrogen and oxygen gas from water. Hydrogen is used as the fuel gas, oxygen is used as the combustion gas, and hydrogen oxygen gas is mixed in the optimal combustion ratio of 2:1.