Due to the low efficiency and high cost of PEM water electrolysis,the industrial oxyhydrogen generators adopt the alkaline electrolysis method.

Due to the low efficiency and high cost of PEM water electrolysis,the industrial oxyhydrogen generators adopt the alkaline electrolysis method.

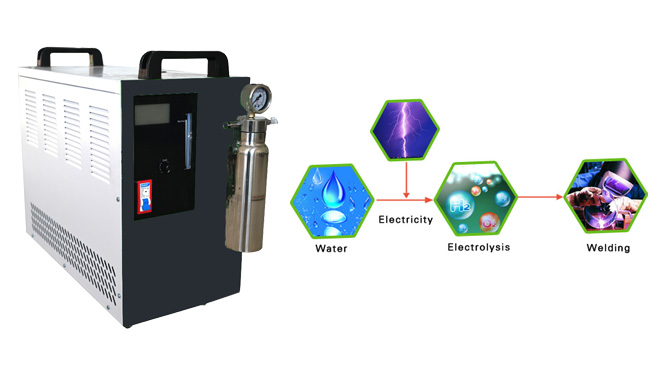

Oxyhydrogen technology uses water as medium to electrolyze water into H2 and O2, fire them to form oxyhydrogen Flame. The temperature of oxyhydrogen flame is as high as 2800 degrees,so that it can weld very fast. The quality and speed of oxyhydrogen flame welding method is higher than liquid gas’s.

| Model Number | TX-HO300 |

| AC Voltage Requirement(V) | 220/110 |

| Phase | single |

| Power Consumption(kw/h) | 1.2 |

| Max. Gas Output(L/h) | 300 |

| Max. Working Pressure(kg/cm2) | 2 |

| Max. Water Consumption(L/h) | 0.17 |

| Water Feed | manual |

| Flame Modifier Feed | manual |

| Dimensions-L*W*H (mm) | 575*246*470 |

| Gross Weight(kg) | 24 |

| Ventilation Space Requirement(mm) | 200 in each direction |

Features of Oxyhydrogen flame

Oxyhydrogen flame is ideal for jewelry and denture industry.

1. Oxyhydrogen flame welding metal fittings and mending sand holes in dentistry.

2.It is also repairing and casting tiny sand holes in the process of jewelry casting and repair.

3.Non-carbon flame disinfection and glass sealing.

The industrial oxyhydrogen generators adopt the alkaline electrolysis method to reduce the production cost and improve the high efficiency of electrolysis.3500L/h Oxyhydrogen flame welding machine is with flange type joint electrolytic cell,1., which can be disassembled for thorough maintenance and repair in the later stage. It is suitable for high flow gas production.

Oxyhydrogen generator is quite safe since it does not require gas cylinders and no risks of leakage and explosion.

Oxyhydrogen generator consumes water and electricity,electrolyze water into H2 and O2,we can use H2 and O2 as source of flame replacing acetylene or natural gas or other fuel.

The oxyhydrogen generator uses electrolytic powder (potassium hydroxide) plus purified water solution

as electrolyte liquid,and adopts the principle of water electrolysis to electrolyze hydrogen and oxygen gas from water. Hydrogen is used as the fuel gas, oxygen is used as the combustion gas, and hydrogen oxygen gas is mixed in the optimal combustion ratio of 2:1.