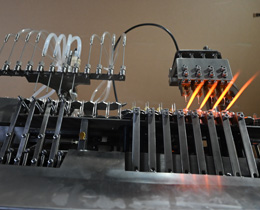

HHO hydrogen generator for boilers consumes water and electricity, electrolyze water into hydrogen gas and oxygen gas, we can use H2 and O2 as source of flame replacing LPG, Propane, Acetylene fuel or natural gas or other oil. For different types of industrial gas/oil fired steam boilers and burners,hho gas can be added for complete combustion and saving energy 10-30%.

How is hho gas produced?HHO gas generator consumes water and electricity, electrolyze water into hydrogen gas and oxygen gas, we can use H2 and O2 as source of flame replacing LPG, Propane, Acetylene fuel or natural gas or other oil.

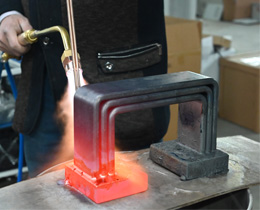

hho gas(brown’s gas) can be alternative gases to replace of fossil fuels LPG,natural gas,gasoline,coal etc?The answer is no.HHO gas flame is concentrated.However,the fossil fuel flame is spread and weak.HHO gas temperature is as higher as 2800degree.When burning,we can add HHO hydrogen gas from HHO generator for boiler into the burner to change the shape of flame and hot heating therefore sufficient combustion.

As the traditional fossil fuel insufficient combustion,it releases hydrocarbons, carbon monoxide, or carbon dioxide emissions which are harm to the human and the environment.Hydrogen gas (H2) burns with intense heat. In air, hydrogen burns with a flame temperature of 2045° C. In contrast, methane (natural gas) burns at only 1325° C. Hydrogen can therefore be used to produce steam at a higher temperature than is achievable with fossil fuel fired boilers.

| Model Number | TX-HO7500 |

| AC Voltage Requirement(V) | 380 |

| Phase | two |

| Power Consumption(kw/h) | 26 |

| Max. Gas Output(L/h) | 7500 |

| Max. Working Pressure(kg/cm2) | 2 |

| Max. Water Consumption(L/h) | 4 |

| Water Feed | automatic |

| Flame Modifier Feed | manual |

| Shell Material | iron plate spray |

| Water Requirement | purified water or distilled water |

| Cooling Method | air cooling |

| Dimensions-L*W*H (mm) | 1310*950*1900 |

| Gross Weight(kg) | 480 |

| Ventilation Space Requirement(mm) | 400mm in each direction |

What are the features and benefits of hho gas for boiler?

The hho gas generator also called brown’s gas play a role of combustion supporting, providing higher temperature for heating and sufficient combustion in combustion chamber.HHO generator for boilers just worked as accessory equipment like water feeding pump in boilers.

More Efficiently and energy saving. For different types of industrial gas/oil fired steam boilers and burners,hho gas can be added for complete combustion and saving energy 10-30%.

Higher temperature when combustion. By adding hho browns gas,it burns at 1900 celcius- at least 20% hotter than other medical incinerators compared with traditional gas.

Environmental Friendly.When brown gas burns,the only byproduct is water vapor.There is no pollutants or toxic carbon emission after burning.

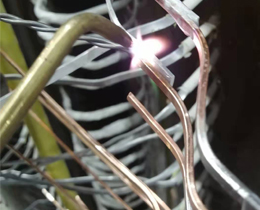

The working medium of oxyhydrogen generator is pure water and electricity, which is electrolyzed with water to produce hydrogen and oxygen gas. Purified water is then supplied and can be added at the daily time, It is operated with low cost and convenient to use.

Oxyhydrogen generator quartz scientific glass vacuum sealing machine is mainly used for oxygen-free and water-free vacuum-sealed storage of samples. The whole setup system consists of oxyhydrogen generator, glass tube vacuum sealing machine, and vacuum pump.