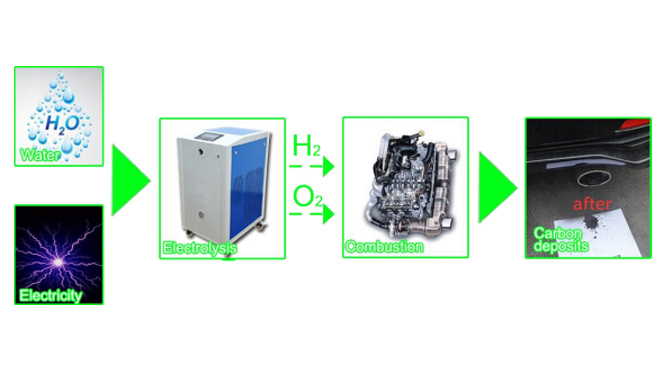

The oxyhydrogen generator uses electrolytic powder (potassium hydroxide) plus purified water solution

as electrolyte liquid,and adopts the principle of water electrolysis to electrolyze hydrogen and oxygen gas from water. Hydrogen is used as the fuel gas, oxygen is used as the combustion gas, and hydrogen oxygen gas is mixed in the optimal combustion ratio of 2:1.

Oxyhydrogen engine carbon cleaning machine only consumes water +electricity to create Oxy-hydrogen gas through water electrolysis.The mixed HHO gas is feed into the engine. The HHO gas burning with fuel can remove the carbon deposits in the engine. After cleaning engine,hydrogen and oxygen are burned into water. Compared with fossil fuel,they do not produce carbon monoxide,carbon dioxide and other toxic gases. Hydrogen engine carbon cleaning treatment is clean and eco-friendly car care way which can instead of traditional disassembled foam and chemical liquid cleaning way.

| Model Number | TX-HO1500 |

| AC Voltage Requirement(V) | 220/110 |

| Phase | single |

| Power Consumption(kw/h) | 4.5 |

| Max. Gas Output(L/h) | 1500 |

| Max. Working Pressure(kg/cm2) | 2 |

| Max. Water Consumption(L/h) | 0.8 |

| Water Feed | manual |

| Suitable For | diesel and gasoline engine |

| Dimensions-L*W*H (mm) | 720*570*1000 |

| Gross Weight(kg) | 120 |

| Ventilation Space Requirement(mm) | 400mm in each direction |

Product Feature

1.Efficient vibration sensor. when the engine accidentally stops, the machine will stop work.

2.Fully automatic control system. There are functions of overpressure shutdown, no gas storage, water shortage reminder and etc.

3.Multiple anti-backfire systems to ensure safe and reliable engine carbon cleaning process.

4.Large capacity water tank. Adding water one time can clean over 50 cars.

5.Advanced cooling system enables continuous machine running.

6.Connect the gas tube into the intake manifold without damaging engine components.

7.Automatically repair oxygen sensors and catalytic converters to extend engine life.

8.It saves fuel,restores engine power,prolong the engine life,and reduces carbon emission.