1. The nozzle of oxyhydrogen flame torch must be tightened to prevent air leakage.

2. The nozzles from small to large A-B-C-D and 4 copper nozzles of 0.3mm, 0.4mm, 0.5mm, 0.6mm.

3. Special large nozzles are limited to individual use.

4. If the machine repeatedly backfires several times or gas tube are burned , it needs to be repaired or replaced a new flame torch.

1. The front end must be locked with the nozzle, and the rear end must be locked with the intake pipe. Except for the nozzle, the torch body and any other parts connected to the machine must not leak air. If found, immediately repair or replace it.

2. Intake gas tube should be high-quality alkali resistant, pressure resistant, and aging resistant transparent soft rubber hose with an outer diameter of 6mm and a wall thickness of 1mm. To ensure personal safety, inferior rubber hoses or other hoses that do not meet the requirements of corrosion resistance, pressure resistance, aging resistance shall not be used.

3. When igniting, always pay attention to the direction of the flame and do not face the human body or any flammable or explosive materials.

4. If the built-in tempering device has a lifespan, if the flame torch fails to backfire (sparks flash in the rubber hose), immediately repair or replace a new torch.

5. If any gas blockage or aging is found in the flame torch or tempering devices, they should also be repaired or replaced timely.

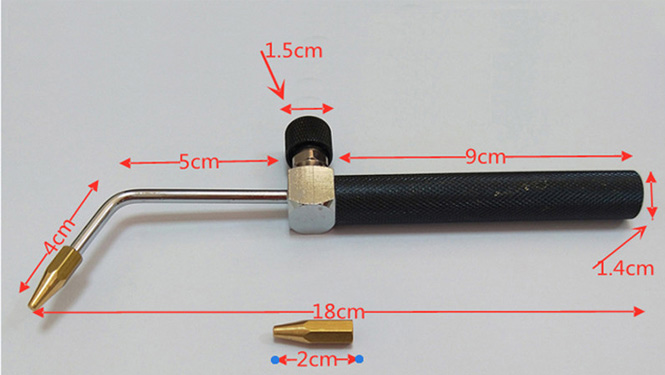

The hydrogen oxygen flame welding torch is composed of a handle, nozzle, holder, control valve, built-in safety device, etc.

The nozzle is made of all copper material with concentrated flame power and is not easily blocked. It is equipped with an anti backfire valve, ensuring safe and reliable use. It is suitable for gold,silver,platinum jewelry welding.

The nozzle is made of all copper material with concentrated flame power and is not easily blocked. It is equipped with an anti backfire valve, ensuring safe and reliable use. It is suitable for various types and brands of acrylic flame polishing machines.