Jewelry processing requires small and soft oxyhydrogen flame.The small oxyhydrogen generators is characterized by easy to carry.

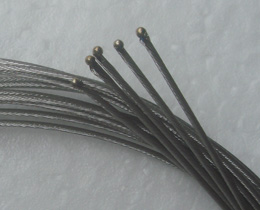

Jewelry processing requires small and soft oxyhydrogen flame.The small oxyhydrogen generators is characterized by easy to carry. The speed of oxyhydrogen flame is very awesome and the welding points are very smooth and beautiful. What’s more,the oxyhydrogen generator can be together with multiple flame torches for several operators.

| Model Number | TX-HO200 |

| AC Voltage Requirement(V) | 220/110 |

| Phase | single |

| Power Consumption(kw/h) | 0.8 |

| Max. Gas Output(L/h) | 200 |

| Max. Working Pressure(kg/cm2) | 2 |

| Max. Water Consumption(L/h) | 0.11 |

| Water Feed | manual |

| Flame Modifier Feed | manual |

| Dimensions-L*W*H (mm) | 450*246*470 |

| Gross Weight(kg) | 20 |

| Ventilation Space Requirement(mm) | 200 in each direction |

Oxyhydrogen welding process introduction

1.Oxyhydrogen flame is stable and does not jump.

2.The oxyhydrogen flame has no carbon emission and no black smoke.

3.HHO gas as fuel comes from water,there is water vapor after burning,no harm to the environment.

4.It can weld kinds of chain and string jewelry which are made of platinum,gold,silver,copper,stainless steel and etc.

5.It is also repairing and casting tiny sand holes in the process of jewelry casting and repair.

Oxyhydrogen generator is quite safe since it does not require gas cylinders and no risks of leakage and explosion.

Oxyhydrogen generator consumes water and electricity,electrolyze water into H2 and O2,we can use H2 and O2 as source of flame replacing acetylene or natural gas or other fuel.

The industrial oxyhydrogen generators adopt the alkaline electrolysis method to reduce the production cost and improve the high efficiency of electrolysis.3500L/h Oxyhydrogen flame welding machine is with flange type joint electrolytic cell,1., which can be disassembled for thorough maintenance and repair in the later stage. It is suitable for high flow gas production.