Traditional flame adopts the liquid gas as fuel and air as combustion-supporting gas,which contains carbon dioxide, carbon monoxide, and nitrogen compounds.

Traditional flame adopts the liquid gas as fuel and air as combustion-supporting gas,which contains carbon dioxide, carbon monoxide, and nitrogen compounds. These substances will impact the quality of pharmaceuticals and bring security hidden danger to the work environment. According to the request of scientific research personnel, PTXSON use alkaline electrolysis technology to seal the ampoules.

Oxyhydrogen flame sealing technology uses water as the medium to electrolyze water into H2 and O2 and fires them to form an oxyhydrogen flame. The temperature of the oxyhydrogen flame is as high as 2800 degrees so that it can seal the ampoules very fast. The quality and speed of the oxyhydrogen flame sealing method are higher than liquid gas’s.

| Model | TX-HO300B |

| Max. Gas Output | 300L/h |

| AC Voltage(V) | 220/110 |

| Rated Power | 1200W |

| Operation Mode | manual by hand |

| Water Feed | manual |

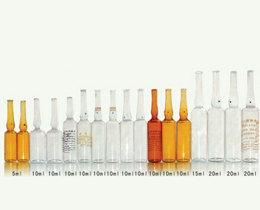

| Ampoule Size | 1-50ml |

| Ampoule Sealing Torch | fixed double flame sealing torch |

| Dimension(L*W*H-mm) | 575*246*470 |

| Net Weight(kg) | 23 |

How does it work?

Putting ampoule bottles on oxyhydrogen flame for heating.When the ampoule bottle is melted,clamp the bottle mouth upward with the tweezer.Remove ampoule bottles and ampoule sealing is finished.

Using dynamic sealing technology to automatically rotary and hold quartz scientific glass with vacuum or argon backfill to prevent sample oxidation. You can chooe oxygen/propane or oxyhydrogen flame torch to melt glass tube. Different size of glass tube clamps can be supplied with your demand.

Oxyhydrogen generator quartz scientific glass vacuum sealing machine is mainly used for oxygen-free and water-free vacuum-sealed storage of samples. The whole setup system consists of oxyhydrogen generator, glass tube vacuum sealing machine, and vacuum pump.

The set of equipment consists of the high vacuum rotary sealing system, the high vacuum pipeline, air inlet, air bleed port, vent valve, and flange of glass tube. The molecular pump vacuum system is a clean high vacuum acquisition device. This device is a vacuum acquisition system based on the principle of vacuum knowledge, utilizing a combination of mechanical pumps and turbomolecular pumps.