The oxyhydrogen flame quartz tube sealing machine is used for vacuum sealing of quartz glass tubes in laboratories of major universities or research institutes,test tubes or borate glass vacuum sealing in the factory etc.

Hydrogen oxygen flame sealing process for quartz glass tubes:

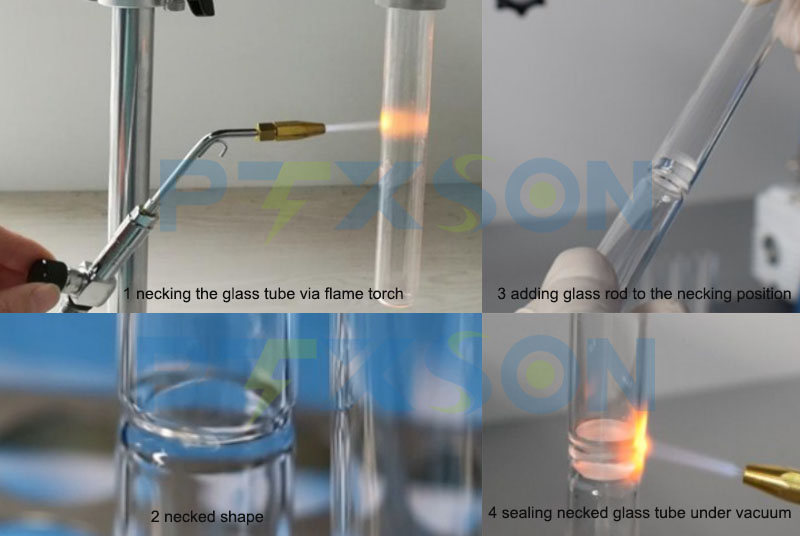

Step 1: Necking a silica glass tube with an oxyhydrogen torch.

Necking begins after vacuuming and the necking area can be burned to a depression.

Step 2: Put in sample and then add glass rod

Put the sample into the quartz tube and slide the glass rod down to the necking position to get stuck.

Step 3, Vaccum sealing the quartz glass tube

After vacuuming and filling with protective gas, vacuum seal the position of glass rod burned.

Step 4 Seal the finished samples

After the sealing is completed, sample labels can be attached for easy identification of samples.

How to choose oxyhydrogen generator for quartz glass tube sealing?

The selection of oxyhydrogen generator depends on the thickness of the glass tube and the requirements for sealing speed, mainly based on the gas production of oxyhydrogen generator.

If the gas production is large, the oxyhydrogen flame is strong and the sealing speed is fast. If the quartz glass tube wall is relatively thick, it should be chosen the high gas production rate oxygen hydrogen generator. The low gas production oxyhydrogen generator is with small flame and slow sealing speed, which is suitable for sealing small or thin-walled glass tubes.