Oxyhydrogen flame generator produce gas on demand without gas storage. It only consume some electricity and water, and produce water vapor after combustion but no carbon emission.

Ptxson Oxy-hydrogen Machine

Oxyhydrogen flame generator produce gas on demand without gas storage. It only consume some electricity and water, and produce water vapor after combustion but no carbon emission.

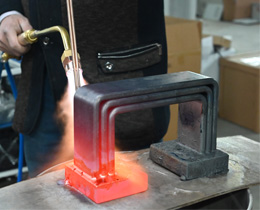

Hydrogen is used as fuel and oxygen is used as a catalyst without additional gas cylinders. It can replace carbon-containing gases such as acetylene, natural gas, and liquefied gas. It has the characteristics of safety, high efficiency, environmental protection, and energy saving.

HHO Generator Welding Machine Can Be Applied The Following Industries

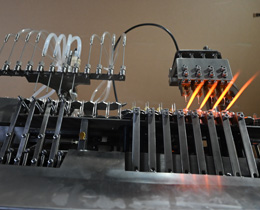

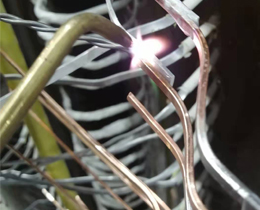

Motor enamelled wire welding,air conditioner copper tube welding, ampoule filling and sealing, and musical instrument welding,power transformer welding, fish hook welding etc.

| Model Number | TX-HO2000 |

| AC Voltage Requirement(V) | 380 |

| Phase | two |

| Power Consumption(kw/h) | 7 |

| Max. Gas Output(L/h) | 2000 |

| Max. Working Pressure(kg/cm2) | 2 |

| Max. Water Consumption(L/h) | 1.1 |

| Water Feed | automatic |

| Flame Modifier Feed | manual |

| Dimensions-L*W*H (mm) | 1100*670*1030 |

| Gross Weight(kg) | 190 |

| Ventilation Space Requirement(mm) | 400mm in each direction |

Oxyhydrogen flame have following features:

Precision oxyhydrogen flame: suitable for various precision welding.

Concentrated oxyhydrogen flame: welding speed is faster than other gases.

Carbon free oxyhydrogen flame: It does not change the rigidity and flexibility of the workpiece.

Convenient operation: No gas cylinders,just consuming pure water and electricity.

The machine can accurately control gas pressure and flow rate, and ensure flame stability.

It can be freely adjusted the flame temperature, diameter, and length. Oxyhydrogen Generator for welding is smooth and uniform welding point.It is a clean carbon free hydrogen gas generator of pollution-free, green and environmentally friendly.

Oxyhydrogen generator is quite safe since it does not require gas cylinders and no risks of leakage and explosion.

Oxyhydrogen generator consumes water and electricity,electrolyze water into H2 and O2,we can use H2 and O2 as source of flame replacing acetylene or natural gas or other fuel.

The industrial oxyhydrogen generators adopt the alkaline electrolysis method to reduce the production cost and improve the high efficiency of electrolysis.3500L/h Oxyhydrogen flame welding machine is with flange type joint electrolytic cell,1., which can be disassembled for thorough maintenance and repair in the later stage. It is suitable for high flow gas production.