Oxyhydrogen generator uses water as medium to electrolyze water into H2 and O2,and fires them to form oxyhydrogen flame.The temperature of oxyhydrogen flame is as high as 2800 degrees so that the oxyhydrogen sealing effect and speed is higher and faster than traditional liquefied gas for ampoule sealing.

We have developed several quartz ampoule sealing methods in your lab scale work.

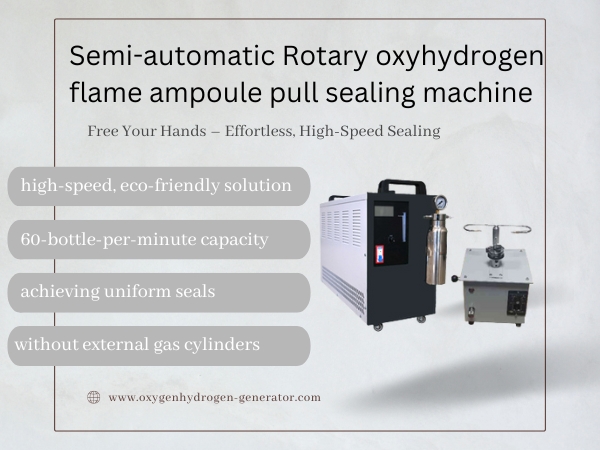

According to the flame torches and sealing method,we have three basic ampule sealing machine for your selection: single ampoule sealing machine TX-HO200A,double ampoule sealing machine TX-HO300B,movable ampoule sealing machine TX-HO300C and Rotary oxyhydrogen flame ampoule pull sealing machine TX-HO400 + TX-R2.

The number 200,300,400 means oxyhydrogen gas output and A,B,C is for different oxyhydrogen torches.

The range of oxyhydrogen ampoule sealing machines is designed to meet different lab requirements, each one with unique output, flame size, sealing speed, and ampoule compatibility:

The temperature of oxyhydrogen flame is as high as 2800 degrees so that it can seal the ampoules very fast. The quality and speed of oxyhydrogen flame sealing method is higher than liquid gas’s.

1. Safety

Oxy-hydrogen flame ampoules sealing machine just uses water and electricity, no gas bottle, no hydrogen gas storage, no leakage and explosive danger.

2. Convenience

it can work just with water and electricity, every litre water can be used 7~8 hours. But liquid gas bottle need to be changed by manual moving, it is very inconvenient.

3. Cleanliness

Oxy-hydrogen combustion just produces little water vapour, there is no harm to the pharmaceuticals. But Liquid gas combustion produces carbon dioxide, carbon monoxide and nitrogen compounds which will impact on the quality of pharmaceuticals.

4. High Efficiency

The speed of oxy-hydrogen flame sealing method is higher than liquid gas’s.

Oxyhydrogen generators offer an innovative ampoule sealing solution by electrolyzing water to produce a high-temperature oxyhydrogen flame of 2800°C, superior to traditional liquefied gas in both speed and sealing quality.

You can add your lab’s efficiency and safety with Ptxson’s advanced oxyhydrogen ampoule sealing machines. Whether you need a single, double, movable, or semi-automatic rotary model, we have a good sealing solution for your lab requirements. Don’t compromise on quality. Choose the technology that offers superior sealing speed and safety.

Explore our range of products today and find the ideal machine for your needs! You can find more details and make the switch to oxyhydrogen sealing technology!