The rotatable vacuum ampoule quartz sealing machine is designed for helping research to seal sample in quartz tube ampule under vacuum at easy and higher efficient yield via oxyhydrogen gas or other flammable gases. This is an excellent tool for preparing thermoelectronic materials sample and grow two dimension crystals which are sensitive to air or easy evaporating.

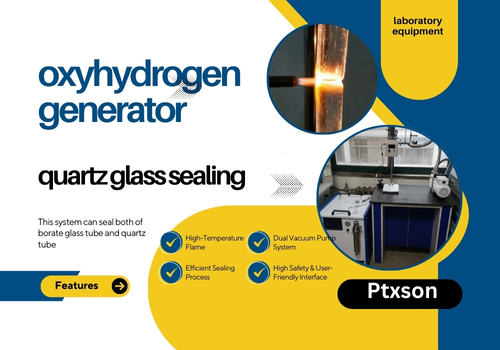

The silica glass tube are widely used for the preparing research samples so that evacuating the silica glass tube and sealing is the necessary operational process for material research. We developed the new quartz vacuum sealing solution via an oxyhydrogen torch.

Sometimes our after-sales service engineer need to go to the university laboratory for on-site oxyhydrogen generator’s installation and debugging. This helps us some learning about their research environment and related experimental device for advanced materials research. The most impressive thing in our mind is the quartz vacuum sealing process. There are two sets of vacuum pumps on the scene. Based on different requirement of vacuum level,there will be two intake and exhaust pipes connecting with the mechanical pump and turbo pump. During vacuum sealing,you may seal silica glass tube with smaller neck or adding quartz rods. The sealing way of adding quartz rod in silica glass tube will be more easier and efficient. Whatever you seal it,one aim is not easy to suck up the mixture powder.

Oxyhydrogen flame temperatures are up to 2800 degrees Celsius, ensuring precise and reliable sealing of quartz tubes. The high temperature is essential for effectively melting silica, which allows for robust seals to prevent contamination.

Safety is an important concern in the laboratory setting. The oxy-hydrogen generator is qualified for its clean-burning properties, producing no harmful burning products, which reduces risks compared with traditional flammable gases. Experts recommend it for environments that require high safety standard.

Industry professionals appreciate the versatility of oxyhydrogen generators, which are suitable for various sealing techniques, including sealing smaller necks or integrating quartz rods. This adaptability is crucial for material researchers sealing different types of samples.

Although initial investments may be high, the long-term savings of increased efficiency and reduced material waste make oxyhydrogen generators a cost-effective solution. The reliability of the equipment minimizes downtime and maintenance costs.

Testimonials from researchers highlight the user-friendly design and the significant improvements in sealing quality and process efficiency. The applications report enhanced outcomes in their experiments, affirming the generator’s value in material research.

In summary, the oxyhydrogen generator is widely used in the laboratory quartz vacuum sealing process due to its efficiency, safety, versatility, cost-effectiveness, and strong user satisfaction.

The portable hydrogen water generator machine uses advanced SPE electrolysis technology for purified hydrogen water production.