Oxyhydrogen generator is electrolyzed from water and produces water vapor after combustion, which is not pollute the environment.

Oxyhydrogen generator is electrolyzed from water and produces water vapor after combustion, which is not pollute the environment. The machine immediately produces hho gas on demand when it is powered on,no gas cylinders are needed. It is a safety gas supply machine, which is equipped with various safety devices of anti-backfire flame torch,built-in anti-backfire flame arrestor gas pipe, internal pressure diagnosis, pressure relief system and etc.

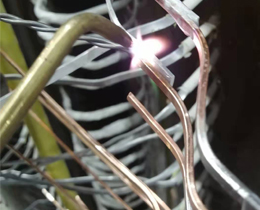

Oxyhydrogen generator is a kind of flame gas welding machine, it is suitable for non-ferrous metal welding and brazing, such as gold, silver, copper, aluminum and so on materials.

We can provide you with one-to-one gas supply scheme used in the process of electric motor brazing,electric motor brazing,air compressor welding.

| Model Number | TX-HO600 |

| AC Voltage Requirement(V) | 220/110 |

| Phase | single |

| Power Consumption(kw/h) | 2.5 |

| Max. Gas Output(L/h) | 650 |

| Max. Working Pressure(kg/cm2) | 2 |

| Max. Water Consumption(L/h) | 0.35 |

| Water Feed | manual |

| Flame Modifier Feed | manual |

| Dimensions-L*W*H (mm) | 930*250*510 |

| Gross Weight(kg) | 35 |

| Ventilation Space Requirement(mm) | 200mm in each direction |

How do you do maintenance regularly?

After the machine running 4 months, or 500 hours, drain out the KOH solution, take high pressure pure water, flushing the electrolysis tank from the top to the bottom, the cell gets clean now. And then, you can refill new KOH solution to get the machine started.

Applied Industrial

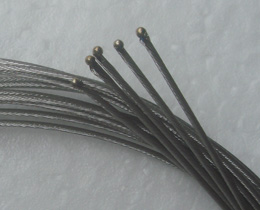

Motor enamelled wire welding and no enamel wire remover,air conditioner copper pipe welding, jewelry welding, and musical instrument welding,power transformer welding, fish hook welding, lighting welding, battery plate welding, flame heating, etc

Product Features

1.Safe and reliable. It can adjust the gas production in real time,water shortage alarm,shut down due to overpressure and overtemperature, no gas storage.

2.Model selection. The model is selected according to the size of the workpiece.

3.A variety of flame torches and nozzles can be selected, showing different flame status.

4.Complete accessories. The flame arrestor, pressure regulator, anti-back fire device are selected to meet different flame requirements.

The oxyhydrogen generator uses electrolytic powder (potassium hydroxide) plus purified water solution

as electrolyte liquid,and adopts the principle of water electrolysis to electrolyze hydrogen and oxygen gas from water. Hydrogen is used as the fuel gas, oxygen is used as the combustion gas, and hydrogen oxygen gas is mixed in the optimal combustion ratio of 2:1.

The industrial oxyhydrogen generators adopt the alkaline electrolysis method to reduce the production cost and improve the high efficiency of electrolysis.3500L/h Oxyhydrogen flame welding machine is with flange type joint electrolytic cell,1., which can be disassembled for thorough maintenance and repair in the later stage. It is suitable for high flow gas production.