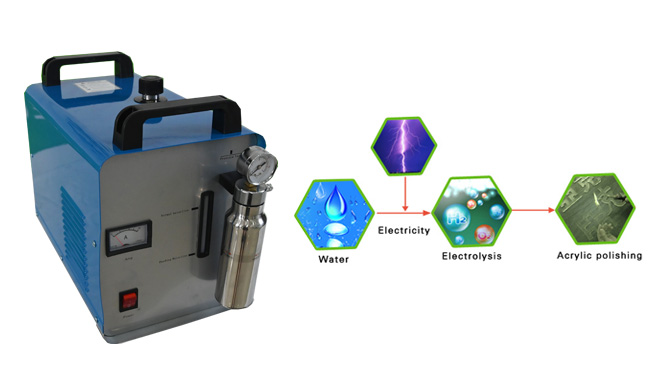

Water electrolysis Technology: Alkaline electrolysis

Application:jewelry welding,acrylic flame polishing

Why do you use oxy-hydrogen for flame polishing?

Oxy-hydrogen flame acrylic polishing machine is a machine using high temperature flame to make acrylic edge smooth and bright. The heating polishing on the acrylic rough surface can be achieved as long as the flame passing by gently, and the acrylic products will become glittery and bright.

| Model | TX-HO100 |

| AC Voltage(V) | 220/110 |

| Rated Power(KW) | 0.4 |

| Gas Output(L/h) | 0-100 |

| Working Pressure | 0.1-0.14Mpa |

| Max. Water Consumption(L/h) | 0.06 |

| Water Feed | manual |

| Dimension(L*W*H-mm) | 520*300*540 |

| Weight(kg) | 15 |

| Vertilation Space Requirement(mm) | 200 |

Oxyhydrogen Advantage

Polishing fast and smooth. The flame temperature is over 2800℃. The concentrated flame make polishing work more fast and smooth.

Safety and convenient. The small machine is convenient for carrying out outdoor work.

Economy. The working medium is some pure water and electricity. The KOH electrolyte liquid is only added in the first using time.

Environment friendly. HHO gas is colorless,odorless,no CO,no CO2 and no any other poisonous and harmful material. There is no carbon emission when combustion.

The industrial oxyhydrogen generators adopt the alkaline electrolysis method to reduce the production cost and improve the high efficiency of electrolysis.3500L/h Oxyhydrogen flame welding machine is with flange type joint electrolytic cell,1., which can be disassembled for thorough maintenance and repair in the later stage. It is suitable for high flow gas production.